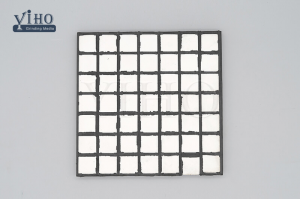

Hybrid Liner Roj Hmab Ceramic Matrix

Hais txog Hybrid Liner Rubber Ceramic Matrix

Koom nrog kev siv cov txheej txheem tshwj xeeb, Hybrid Liner muab ob lub liner cov ntaub ntawv thiab lawv cov khoom zoo.Sab hauv yog ua los ntawm polyurethane thiab tiv thaiv cov seem seem thiab pob txha cov qauv ua tsaug rau nws cov yam ntxwv poob siab absorbing.Nyob rau tib lub sijhawm, nws ua kom zoo tshaj qhov kev faib tawm thoob plaws tag nrho cov seem seem, ob qho tib si rau kev ua haujlwm siab thiab ua haujlwm ntawm lub tshuab nqus tsev.Sab nraud ntawm lub liner thiab lub tshuab nqus tsev sib xyaw ua ke yog ua los ntawm silicone, ua pov thawj hauv kev siv txhua hnub ua tsaug rau nws qhov muaj zog.Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog thaum lub tshuab nqus tsev yog folded nyob rau hauv lub qhov (socket) los tsim ib lub foob rau lub kaw lus.

Hybrid Liner Rubber Ceramic Matrix Daim Ntawv Thov

Hais txog kev puas tsuaj nrog rau cov roj hmab hauv ob sab phlu, cov lus hauv qab no yuav tsum tau xav txog.

1- Muaj ob hom kev puas tsuaj ib qho yuav ntsib, impingement thiab zawv zawg.

2- Impingement abrasion tshwm sim thaum cov khoom tawm tsam ntawm cov roj hmab (lossis lwm qhov chaw).

3- zawv zawg abrasion tshwm sim thaum lwm qhov chaw swb hla cov roj hmab.

4- Nyob rau hauv txhua rooj plaub, kev puas tsuaj yuav tsum tau ua ke ntawm impingement thiab zawv zawg.

5- Feem ntau impingement abrasion tshwm sim nyob rau hauv chutes, sandblast hose thiab nyob qhov twg rebound yog pom.

6- Nyob rau hauv cov txheej txheem impingement, hais tias ntog rau saum npoo thiab txhua qhov kev ntxhov siab uas tsim tau raug faib sib npaug yog tias cov roj hmab yields yooj yim, tshwj xeeb tshaj yog thaum cov khoom tawm tsam ntawm 90 ° lub kaum sab xis rau saum npoo.

Cov ntaub ntawv ntawm Ceramics (Alumina + Reaction Bonded Silicon Carbide Vuas)

| Qeb | 92% Al2O3 | 95% Al2O3 |

| ZrO2 | / | / |

| Qhov ntom(g / cm3) | >3.60 ib | >3,65g :ua |

| HV 20 | ≥950 | ≥1000 |

| Pob zeb Hardness HRA | ≥82 | ≥85 |

| Bending zog MPa | ≥220 | ≥250 |

| Compression zog MPa | ≥1050 | ≥1300 |

| Fracture Toughness (KIc MPam 1/2) | ≥3.7 | ≥3.8 |

| Hnav ntim (cm3) | ≤ 0.25 | ≤ 0.20 |

| Silicon CarbideCov ntaub ntawv(RBSiC) | ||

| Index | Tus nqi | Cov txiaj ntsig kuaj |

| Sic | / | ≧90 |

| Kub | ℃ | 1380 |

| Tshwj xeeb ceev | g/cm3 | ≧ 3.02 |

| Qhib Porosity | % | <0.1 |

| Modulus ntawm elasticity: | Gpa | 330Gpa (20 ℃) 300 Gpa(1200 ℃) |

| Moh's Hardness | / | 9.6 ib |

| Khoov zog | Mpa | 250 (20 ℃) / 280 (1200 ℃) |

| Compression zog | Mpa | 1150 |

| Coefficient ntawm thermal expansion: | / | 4.5K^(-3)*10^(-5) |

| Coefficient ntawm thermal conductivity: | W/mk | 45 (1200 ℃) |

| Acid Alkaline pov thawj | / | Zoo heev |