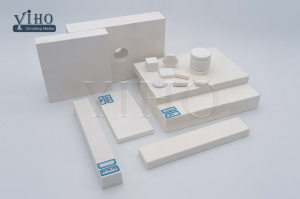

Dry Pressed Alumina Hnav phaj

Hais txog YIHO Alumina Hnav Plate

Ua kom lub neej thiab kev ua haujlwm ntawm koj cov khoom muaj nqis ua haujlwm.

Wear Plates yog tsim thiab tsim rau lawv daim ntawv thov tshwj xeeb, kom ntseeg tau tias cov phaj raug yog ib txwm pom zoo thiab ntsia.

Ntxiv nrog rau kev muag khoom ntawm daim hlau, HICTECH muaj peev xwm txhim kho uas xa cov neeg siv khoom txaus siab thiab tus nqi tshwj xeeb.Ua kom yooj yim los ntawm peb cov kev paub dhau los thiab txhim khu kev qha ntawm qhov chaw pabcuam, peb yuav tswj hwm koj qhov project tag nrho, los ntawm lub tswv yim thiab kev ntsuas theem, mus txog rau kev tsim khoom, xa khoom, kev teeb tsa, kev saib xyuas thiab kev pabcuam tomqab muag / kev txhawb nqa.

Hnav daim hlau yog engineered kom haum rau txhua daim ntawv thov thiab muaj ntau yam kev xaiv kho, steel studded backing phaj, weld ntawm kev xaiv thiab ncaj substrate bonding.

Alumina Ceramic Hnav Daim Hlau

Wear Plates yog tsim los rau cov qauv zoo tshaj plaws thiab cov lus qhia tshwj xeeb, ua rau lawv zoo dua rau lwm yam khoom hauv khw.

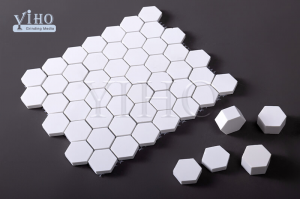

Nta

• Cov yam ntxwv zoo dua hnav

• Dampens cuam tshuam

• txo suab nrov

• Txo cov sij hawm poob

• Tus nqi qis ib tonne ROI

• Haum rau lub hom phiaj

Kev siv Alumina Hnav Plate

• Chutes

• Hoppers

• Hloov cov ntsiab lus

• Sib tsoo thiab tshuaj ntsuam

• Milling

• Tsheb ciav hlau thiab nkoj thauj khoom

Alumina Hnav Plate Specification

| Kev sib xyaw | Thicknesses | Qhov ntom |

| Zirconia Toughened Alumina | 12mm, 25mm, 50mm | 4.2g / cm33 |

| Alumina 92% / 95% Al203 | 3 ~ 75 hli | 3.65 & 3.72g / cm33 |

| Alumina 92% Al203 / Ntuj Roj Hmab | 8mm-63 hli | / |

| Alumina 92% Al203 / High Tensile Polymer | 10mm-63 hli | / |

| Polyurethane | 3 hli-20mm | / |

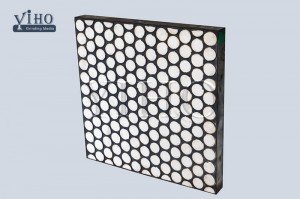

Installation ntawm hnav ceramic liner

1. Directly nplaum paste: siv chav tsev kub lossis kub kub muaj zog inorganic nplaum paste rau nruab.Nws yog ib qho yooj yim rau nruab thiab haum rau me me cuam tshuam nrog kev ua haujlwm kub hauv qab 350 ℃.

2. Stud welding: nws tuaj yeem siv rau cov ntaub ntawv kub thiab cov ntaub ntawv uas muaj kev cuam tshuam loj heev.Cov neeg kho tshuab nws tus kheej-locking quab yuam thiab inorganic adhesive tuaj yeem ua kom ntseeg tau tias lub liner tsis poob.

3. Prefabricated ceramic liner installation: ceramic yuav tsum tau nruab rau ntawm lub phaj steel ua ntej ua 2-hauv-1 ceramic liner (ceramic + steel phaj), lossis 3-hauv-1 ceramic liner (ceramic + roj hmab + steel phaj) , thiab tom qab ntawd los ntawm vuam lossis countersunk bolts rau nruab rau ntawm cov khoom siv, uas yooj yim kho thiab hloov.

High Purity Alumina cuam tshuam-resistant hnav-resistant ceramic hauv ob sab phlu

tuaj yeem hloov cov manganese steel liner, uas tuaj yeem daws qhov teeb meem hnav.Lub siab kub cuam tshuam-resistant hnav liner yog welded nyob rau hauv cov khoom siv los ntawm stud welding ntawm toughened ultra-thick ZTA, thiaj li mus tsim ib tug muaj zog anti-hnav txheej.Qee cov bulges kheej kheej tuaj yeem tsim rau hauv ob sab phlu kom ntxiv dag zog rau nws cov kev cuam tshuam.Rau kev yooj yim ntawm kev txhim kho thiab hloov pauv, cov kab hluav taws xob ceramic tuaj yeem txuas rau ntawm lub phaj steel thiab tom qab ntawd txuas rau ntawm cov khoom siv los ntawm vuam lossis countersunk bolts.