Engineering Hnav Ceramic Matrix

Hais txog Hnav Ceramic Matrix

Abrasion yeej ib txwm tsis tuaj yeem zam hauv kev ua thiab thauj cov ntaub ntawv ntau.Cov khoom poob qis ua rau muaj kev cuam tshuam tshwj xeeb.Peb muab cov kev daws teeb meem zoo tshaj plaws rau cov neeg siv khoom nrog cov khoom siv zoo tshaj plaws ceramic hnav matrix (nrog / tsis muaj steel phaj thiab ntsia liaj qhov rooj), thiaj li ua tiav cov txiaj ntsig zoo hauv kev ua kom muaj kev cuam tshuam thiab txo qhov puas thiab lub suab nrov.

Ceramic Conveyor Wear Lineers yuav txo koj cov nqi khiav lag luam ntau thaum piv rau lwm cov khoom siv hauv ob sab phlu.

Yiho manufactures ntau yam conveyor hnav liners nyob rau hauv tej zaum yuav xaiv thiab ntau thiab tsawg xaiv los ntawm.Tsim los tswj cov tawv tawv pob zeb mining daim ntawv thov.Abrasion resistant, modular, high-hnav cov ntaub ntawv rau kab siv chutes, thiab bin tej thaj chaw.

Hnav Ceramic Matrix Nta

* Kev cuam tshuam tsis zoo heev

* Tsawg kev sib txhuam coefficient

* Txo suab nrov

* yooj yim thiab ceev montage

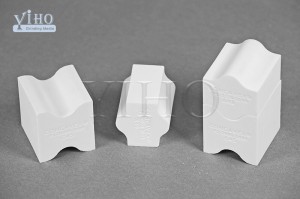

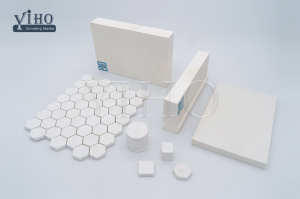

Hom Ceramics

Lub tog raj kheej| Hex Pobzeb | Rectangular |Square | Lub voos xwmfab

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Technical Data:

| Qeb | HWV 92 | HC95 ua | HCT 95 | HC99 ua | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Qhov ntom (g / cm3 ) | >3.60 ib | >3,65g :ua | >3.70 ib | >3.83 ib | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Pob zeb Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Bending zog MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Compression zog MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Fracture Toughness (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Hnav ntim (cm3) | ≤ 0.25 | ≤ 0.20 | ≤ 0.15 | ≤0.10 | ≤ 0.05 |

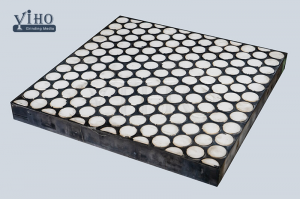

Hom Hnav Matrix

* Roj hmab backed ceramic matrix

* Hlau thaub qab roj hmab ceramic matrix

Dimension ntawm Ceramic Hnav Matrix

Tsis tu ncua & Customized,

Max L800 * W800mm

Kev lag luam suav nrog rau Ceramic Hnav Matrix

• Sib sau ua ke

• Asphalt

• Cement

• Tshuaj

• Coal raug rho tawm haujlwm

• Hwj chim

• Coal

• Kev ua haujlwm

• Kev khawb av

• Cov chiv

• Fiberglass

• ya tshauv

• Khoom noj khoom haus

• Kev ua haujlwm

• Foundry

• Frac Xuab zeb

• iav & Frit

• Nplej

• Gypsum

• Hlau & Hlau

• Mineral

• Kev ua haujlwm

• Kev khawb av

• Roj Sands

• Roj & Roj

• Petrochemical

• Potash

• Pulp & Ntawv

• Chaw txua txiag zeb

• Rov ua dua

• vov tsev

• Khoom siv

• Xuab zeb & Gravel

• Qab Zib

• Cov dej khib nyiab

• Cov khoom siv hmoov / ntau

• Kev tuav

• Kev Lag Luam Pabcuam

• Muaj

Daim ntawv thov ntawm Ceramic Wear Matrix

• Tshauv Slurry Kab

• Pob Mine Lineers

• Bark Feed Screws

• Bark Handling Chutes

• Lub luj tshib rov qab

• Clinker Hoppers

• Coal Troughs

• Conveyor Transitions

• Cyclones

• Draft Lineers

• Dust Collector Liners

• Ntxuam tawm

• Cov vaj tsev

• Tawm cov kav dej

• Pub Chutes

• Lub luj tshib rov qab

• Gas Scrubber Lines

• Hog Fuel Handling

• ID Ntxuam Vaj Tsev

• Mill Lub Cev Tsev

• Ore Bunkers

• Pulverizer Lub Cev

• Pulverizer Classifier

• Cones

• Pulverizer Discharge

• Valves

• Pob zeb txaj phab ntsa Liners

• Silos & Bunkers

• Kev hloov pauv

• Tsheb thiab Rail Tsheb

• Coal Dumps

• Lub thawv ntxhua khaub ncaws

• Wennberg Screws