Conveyor Chute Lining Impact Liner Vaj Huam Sib Luag

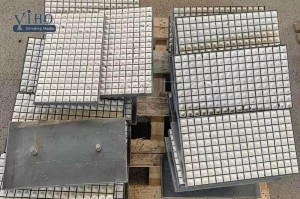

Chute Linings yog tsim los ua ib feem tseem ceeb ntawm lub tshuab conveyor.Peb pre-engineered chute hauv ob sab phlu tiv thaiv thiab cushions lub chute los ntawm cov khoom raug tuav;Skirt Liners tiv thaiv cov ntaub ntawv khiav tawm ntawm kev khiav tawm thiab ua rau cov chaw thauj khoom thauj khoom puas.Peb tuaj yeem tsim, tsim, tsim thiab nruab chutes, thiab kuj kho thiab rov kho cov chutes uas twb muaj lawm.

Kev sib xyaw ua ke ntawm txoj kab ncaj nraim nrog cov qauv chute raug txhim kho tag nrho cov kev ua haujlwm ntawm lub cev thiab ua kom cov khoom xa tuaj zoo tshaj plaws, txhawb kev khiav dej num zoo, kev tiv thaiv plua plav thiab txo qis hauv lub chute.

Cov khoom siv ceramic

92%, 95%, 99% -Al2O3 ceramic vuas (Lub tog raj kheej, square, duab plaub lossis

hexagonal "SW") vulcanized nyob rau hauv tshwj xeeb roj hmab nrog CN bonding txheej.

| Al2O3 | SiO 2 | CaO | MgO | Na2O | |||

| 92%~ 99% | 3 ~ 6% | 1 ~ 1.6% | 0.2 ~ 0.8% | 0.1% | |||

| Lub ntiajteb txawj nqus (g / cc) | > 3.60 | > 3.65 | > 3.70 | ||||

| Pom tseeb porosity (%) | 0 | 0 | 0 | ||||

| Bending zog (20 ℃, Mpa) | 220 | 250 | 300 | ||||

| Compressive zog (20 ℃, Mpa) | 1050 | 1300 | 1600 | ||||

| Rockwell hardness (HRA) | 82 | 85 | 88 | ||||

| Vickers hardness (HV20) | 1050 | 1150 | 1200 | ||||

| Moh lub hardness (scale) | ≥9 | ≥9 | ≥9 | ||||

| Thermal Expansion (20-800 ℃, x10-6 / ℃) | 8 | 8 | 8 | ||||

| Kev puas tsuaj (Cm3) | 0.25 | 0.2 | 0.15 | ||||

Ceramic Conveyor Liner Properties

• CN bonding txheej muab ceev thiab ntev adhesion

• Kev puas tsuaj siab tshaj plaws

• Txo cov nqi khiav lag luam

• Lub neej ua haujlwm ntev ua kom cov khoom siv tau zoo

• Zoo tiv thaiv huab cua

Thaj tsam ntawm daim ntawv thov ntawm Ceramic Rubber Liner

Wear Solutions muaj kev paub tshwj xeeb hauv kev siv ntau yam ntaub ntawv hauv ob sab phlu xws li Basalt, Alumina, Silicon Carbide, polyurethane thiab cov vuas luaj.Cov nkoj thiab cov khoom cog muaj xws li hloov chutes, launders, thiab cyclones, thiab lwm yam.

• Sab hauv tiv thaiv hnyav heev los ntawm kev puas tsuaj ntawm kev kub ceev

• Rau kev yooj yim mus rau nruab nrab daim ntawv thov hauv mining, gravel, xuab zeb thiab pob zeb tawg mills thiab lwm yam kev lag luam sectors

• Hauv cov ntawv thov xws li cov kav xa dej, vibratory feeders, cyclones, skips, bunkers, chutes, loading point, slides, hoppers, silos