Ceramic raj thiab qhov tshwj xeeb-zoo li tus

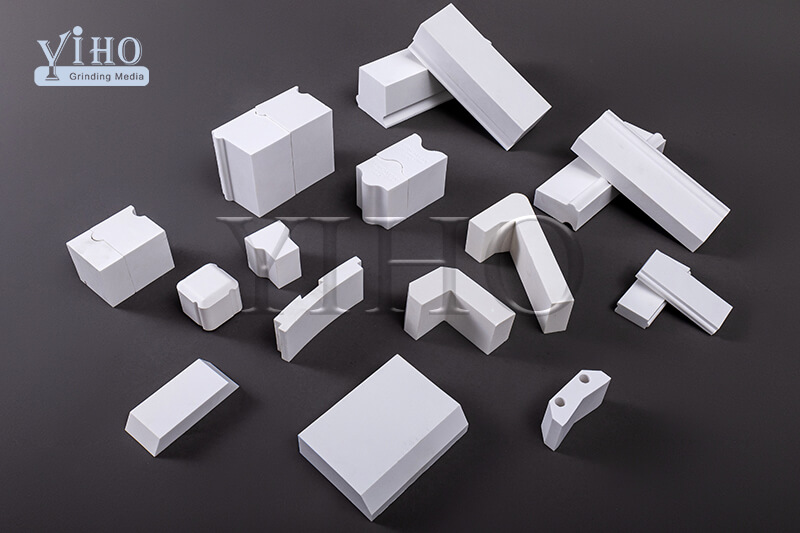

Cov qauv khoom:

| Qeb | HWV 90 | HWV 92 | HC95 ua | HCT 95 | HC99 ua | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Qhov ntom | 3.50g / cm33 | 3.60g / cm33 | 3.65g / cm33 | 3.70g / cm33 | 3.83g / cm33 | 4.10g / cm33 | 5.90g / cm33 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Pob zeb Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending zog MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression zog MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Hnav ntim | ≤ 0.28 cm3 | ≤0.25cm3 | ≤ 0.20cm3 | ≤0.15cm3 | ≤ 0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Piv txwv ntawm Kev Siv

Lus Cim: Peb tuaj yeem ua alumina hnav pobzeb raws li koj xav tau.

Nta

Siab hardness

Rockwell hardness ntawm siab alumina ceramics yog mus txog HRA80-90 uas yog thib ob tsuas yog pob zeb diamond thiab deb tshaj hnav-resistant steel stainless.

Zoo heev hnav tsis kam

Kev hnav tsis kam ntawm siab alumina ceramics yog 266 npaug ntawm cov hlau manganese thiab 171.5 npaug ntawm cov chromium cam khwb cia hlau siab. ua hauj lwm tej yam kev mob.

Corrosion kuj

High alumina ceramics yog inorganic oxides nrog cov qauv molecular ruaj khov thiab tsis muaj electrochemical corrosion, yog li lawv tuaj yeem tiv taus yaig ntawm cov kua qaub, alkali, ntsev tov thiab cov kuab tshuaj organic.

Thermostability

Ua hauj lwm kub ntawm siab alumina ceramics yuav siab li 1400 ℃.

Zoo tus kheej-lubricity

High alumina ceramics muaj cov khoom ntawm nws tus kheej-lubricity thiab inadhesion, qhov roughness tsuas yog 1/6 ntawm cov kav hlau steel yog li tsis tshua muaj dej tsis kam.

Lub teeb nyhav

Qhov ceev ntawm high alumina ceramics yog hais txog 3.6g / cm3, uas tsuas yog ib nrab ntawm cov hlau, yog li yooj yim rau kev tsim kho thiab installation.

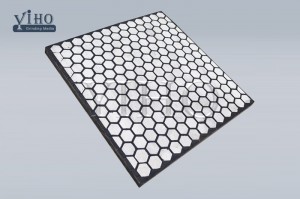

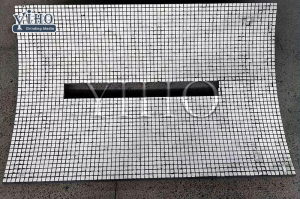

Hnav cov kev daws teeb meem peb muab

Qhov no yog txheej txheem nyuaj.Our engineers nkag siab txog cov teeb meem hnav thiab qhia meej

kev daws teeb meem kom tau raws li koj qhov chaw ua haujlwm.Cov khoom siv, kam rau ua, flatness, txuas txoj kev, thiab cov nqi ntawm cov khoom yog suav tias yog nyob rau hauv ib tug hnav s

Daim ntawv thov

• Chutes/Hoppers

• Classifier Cones

• Cyclone Separators

• Luj tshib

• Ntxuam Vaj & Hniav

• Kab Yeeb

• Nozzles

• Hnav Panels

Kev lag luam

• Kev tsim hluav taws xob thee hluav taws xob

• Abrasive kov

• Kev ua tshuaj lom neeg

• Kev ua zaub mov

• Hlau / Hlau Manufacturing

• Mineral processing

• Powder/Bulk Solids Conveying

• Pulp & Paper Manufacturing

• Pulverizing & Sib tsoo