Abrasive Alumina Tube Tes Tsho Pipe Luj Tshib Linings

Khoom Taw Qhia

Alumina (Al2O3) yog ib qho ntawm cov kev qhia dav dav tshaj plaws, kev siv lub hom phiaj dav dav.Tag nrho cov alumina yog ib qho nyuaj heev thiab hnav resistant, nrog rau siab compressive zog txawm tiv thaiv huab cua kub thiab corrosive ib puag ncig.Alumina kuj yog cov hluav taws xob zoo heev thiab muaj roj nruj.Aluminium Oxide Ceramic yog tsim los ntawm firing ib nruj packed hmoov daim ntawv ntawm Al2O3 uas muaj xws li ib co binder khoom.Cov qib kev lag luam muaj nyob ntawm 90% mus txog 99.8% nrog cov purity siab dua ua kom muaj zog dua me ntsis.Nws yog ua tau rau tshuab alumina siv pob zeb diamond sib tsoo cov tswv yim.Polishing kuj tseem tuaj yeem ua tau, nrog rau qib siab cuam tshuam los ntawm alumina grain loj thiab cov txheej txheem ntau lawm, txawm tias nias los yog extruded.

| Siab Hardness | Tsawg Coefficient ntawm Thermal Expansion |

| Zoo heev Hluav Taws Xob Insulator | Mechanically ruaj khov ntawm qhov kub thiab txias |

| Zoo Thermal Shock Resistance | High density, non-porous thiab nqus nruj |

| Resistant Abrasive Wear thiab Tshuaj Tiv Thaiv | ...... |

Cov khoom siv

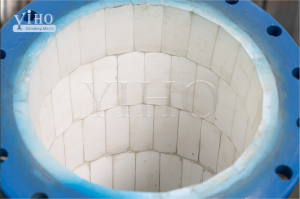

Dab tsi yog Ceramic Pipe Sleeve?

Lub ntsiab raw khoom ntawm hnav resistant ceramic nplhaib yog ib yam tshwj xeeb ntawm tej hub nrog AL2O3 raws li cov thiab tsis tshua muaj hlau oxide raws li cov flux, uas yog melted los ntawm kub kub ntawm 1700 ° C.Lub Ceramic Sleeves Lined Yeeb Nkab ua ib feem, thiab tom qab ntawd sib sau ua ke rau hauv cov yeeb nkab steel nrog peb lub zog siab-kub-resistant epoxy nplaum.

Alumina ceramic raj yog cov hnav tsis kam, acid thiab alkali tsis kam, ua haujlwm ntev lub neej ntawm cov khoom siv thiab suav tias yog qhov kev xaiv zoo tshaj plaws ntawm cov khoom siv tiv thaiv hnav thiab tiv thaiv corrosion;Hnav tsis kam ntawm ceramic yog 10 npaug tshaj qhov tshwj xeeb manganese, 10 zaug rau siab chrome cam khwb cia hlau;Hardness yog ntau dua li cov hnav-resistant steel thiab stainless hlau.Daim ntawv thov: Roj, mining, steel thiab fais fab kev lag luam.

Technical parameters

| Alumina / RBSIC ceramic raj | |||

| Khoom siv | Alumina & RBSiC Silicone Carbide | ||

| Hom | FIRSTAR | ||

| Lub teb chaws ntawm keeb kwm | Zibo, Suav | ||

| Xim | Dawb | ||

| Hom | Tube | ||

| Loj | OD | ID | Ntev |

|

| 70-750 hli | 30-710 hli | 200-500 hli |

| Txoj kev molding | Isostatic nias | ||

| Kev ceev ceev | 3.02 & 3.65 & 3.70g / cm3 | ||

| Al2O3% | 92% / 95% / Silicon carbide | ||

| Kev nqus dej | ≤ 0.01 | ||

| Kev puas tsuaj (cm3) | 0.1 ~ 0.25 hli | ||

Daim ntawv thov

| Kev lag luam | |

| 1. Abrasive khoom | Sib tsoo log granules |

| 2. Aluminium nroj tsuag | Calcined alumina, bauxite, electrode, carbon, crushed da dej |

| 3. Hlau & Hlau | Sinter plua plav, limestone, txiv qaub txhaj tshuaj, thee, hlau carbide, alloy additives |

| 4. Mineral wool & rwb thaiv tsev khoom | Perlite, pob zeb hmoov av, refractory fibers, ntau lawm pov tseg, plua plav los ntawm kev ua haujlwm sawing |

| 5. Cov chaw tsim khoom | Moulding xuab zeb, plua plav sau |

| 6. iav nroj tsuag | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, nplej ua, pub mills | Pob kws, barley, taum soy, malt, cocoa taum, sunflower noob, nplej hulls, malting nroj tsuag |

| 8. Cement | Clinker plua plav, limestone, cement, ya tshauv, thee, blast furnace slag |

| 9. Cov nroj tsuag tshuaj | Caustic txiv qaub, chiv, txiv qaub hmoov av, chrome ore, xim pigments, yas pallets nrog iav fibers |

| 10. Mineral mining nroj tsuag | Kiln pub, ore concentrate, thee tailings, plua plav |

| 11. Coal fired power stations | Coal, ya tshauv, pyrites, slag, tshauv, limestone |

| 12. Coal mines | Coal plua plav, mine khib nyiab rau rov qab filling |

| 13. Technical carbon cov khoom | Technical carbon, plua plav, graphite rau electrodes |